| What are the advantages of your CNC machines compared to those of major Japanese manufacturers? |

Thank you very much for your interest in our CNC machines! |

| What is the horsepower (HP) of the machine spindle? |

| Spindle: 7.5 HP (5.5 KW) X-axis: 2.0 HP(1.5 KW) Y-axis: 2.0 HP (1.5 KW) Z-axis: 2.68 HP (2.0 KW) Please let me know if these specifications are accurate and suitable. |

| What is the distance from the spindle nose to the worktable surface? |

| The distance from the spindle nose to the worktable surface is 150 to 480 mm. If a 4th axis is installed, the spindle will be elevated by 160 mm. |

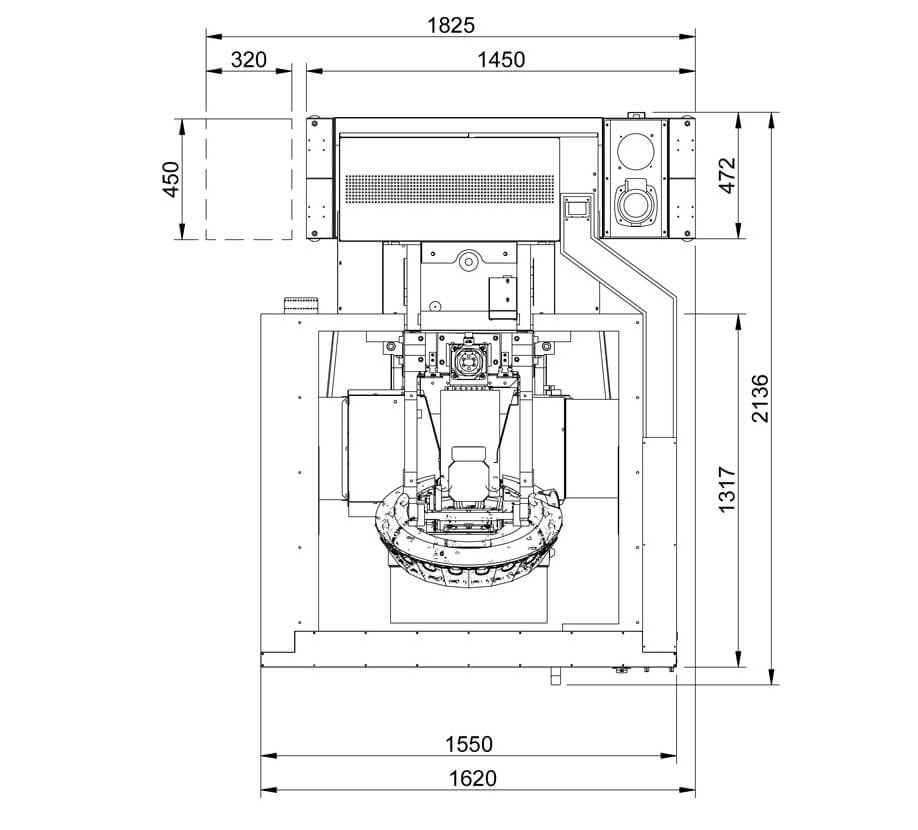

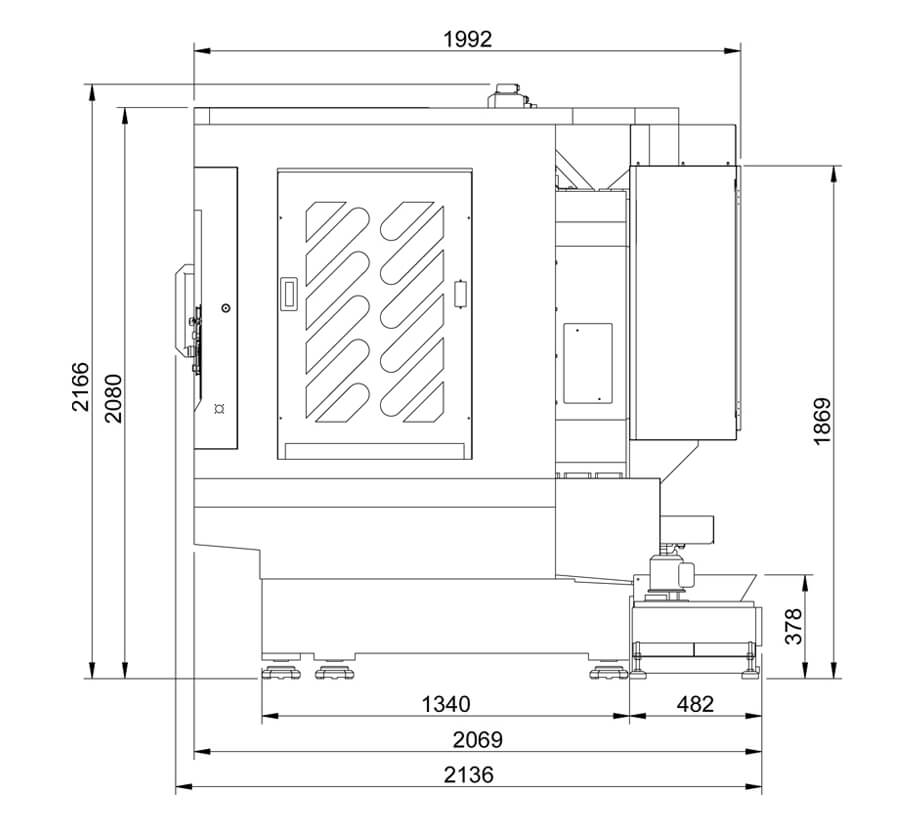

| What is the overall floor space occupied by the machine? |

The overall floor space occupied by the CNC machine: Length 162 cm * Width 213 cm * Height 216 cm.  |

| What is the weight of the machine? |

| The machine weighs 2.8 tons.

|

| What are your actual sales case studies like? Since you are a new CNC machine brand, I’m concerned about the stability and reliability of your machines. |

| Since 2019, this CNC machine has been developed and authorized by the Precision Machinery Research Development Center, and over 70 units have already been sold. All the issues encountered during the development phase have been fully resolved over the years, ensuring exceptional durability and stability.

|

| How long is the warranty? |

| Our CNC machines come with a 2-year warranty, ensuring that the machines you purchase maintain high stability during your operations, giving you complete peace of mind. Additionally, we have a professional technical support team. If you encounter any issues after purchasing a CNC machine, feel free to contact us at +886-4-24930678, or use our online consultation service (WhatsApp: +886-937799162). We are committed to providing expert after-sales support to quickly resolve any technical challenges, ensuring your CNC machine operates smoothly and reliably over the long term. |

| Do you offer fixture and jig design services? |

| Yes, we do. Feel free to bring your workpiece or send us your drawing for evaluation. In addition to being a professional CNC machine manufacturer, we have 40 years of experience in fixture and jig production. Whether it's fixture design or clamping applications, we can provide you with the best CNC clamping solutions to help optimize your processing efficiency. |

| What type of oil does the CNC machine use? |

| Standard equipment includes a grease lubrication system, synchronized with Japanese specifications. |

| What is the weight capacity of the tool magazine? |

| We use a BT-30 tool magazine, which has a weight capacity of 3.5 kg. |

SHANG ZUAN CO., LTD.

SHANG ZUAN CO., LTD.