Spindle Type-Inside Spindle : MT3

Spindle Type-For Chuck : JT6

Working Ability-Steel (S45C) : 5-25

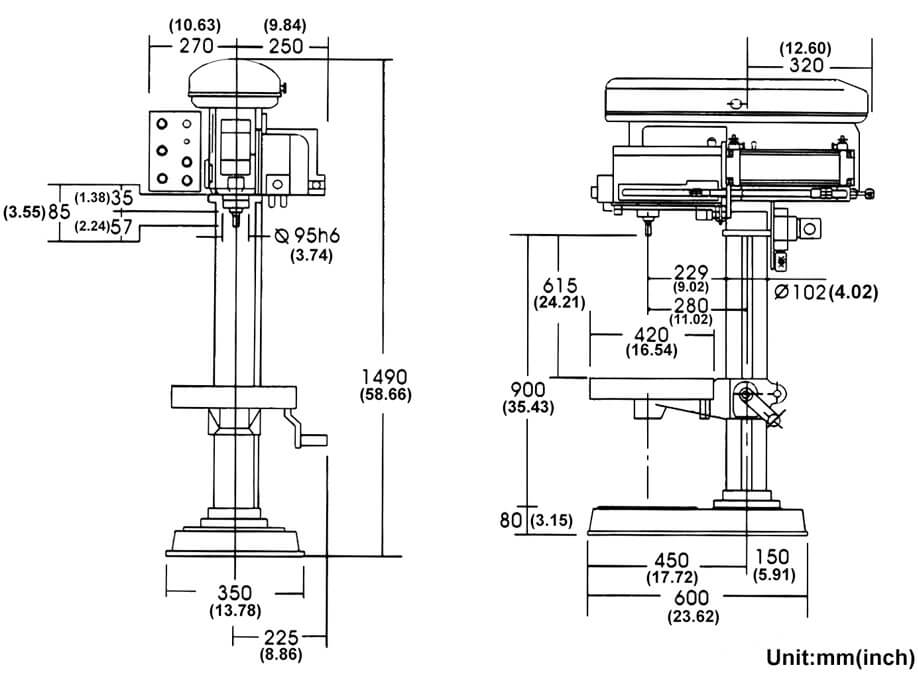

Spindle Travel : 133mm

Motor : 2HP-6P

Spindle Speed RPM (Steps) :

50HZ : 160-1342

60HZ : 190-1610

Weight : 229kg With Hydrauli Unit

-

Stroke : Automatic-Hydraulic

Spindle Type-lnside Spindle : MT3

Spindle Type-For Chuck : JT6

Working Ability-Steel (S45C) : 5-25

Spindle Travel : 133mm

Motor : 2HP-6P

Spindle Speed RPM (Steps)-50HZ : 160-1342(9)

Spindle Speed RPM (Steps)-60HZ : 190-1610(9)

Weight : 229kg With Hydrauli Unit

Pro Tip:

1. Keep drill bits sharp. Use proper lubrication and cooling for peak performance.

2. Adjust Spindle Speed for specific materials and drill sizes.

-

鑽台規格Stroke : Automatic-Hydraulic

Spindle Type-lnside Spindle : MT3

Spindle Type-For Chuck : JT6

Working Ability-Steel (S45C) : 5-25

Spindle Travel : 133mm

Motor : 2HP-6P

Spindle Speed RPM (Steps)-50HZ : 160-1342(9)

Spindle Speed RPM (Steps)-60HZ : 190-1610(9)

Weight : 229kg With Hydrauli Unit

Pro Tip:

1. Keep drill bits sharp. Use proper lubrication and cooling for peak performance.

2. Adjust Spindle Speed for specific materials and drill sizes.

Expert Craftsmanship

Artisanal quality in every drill press.

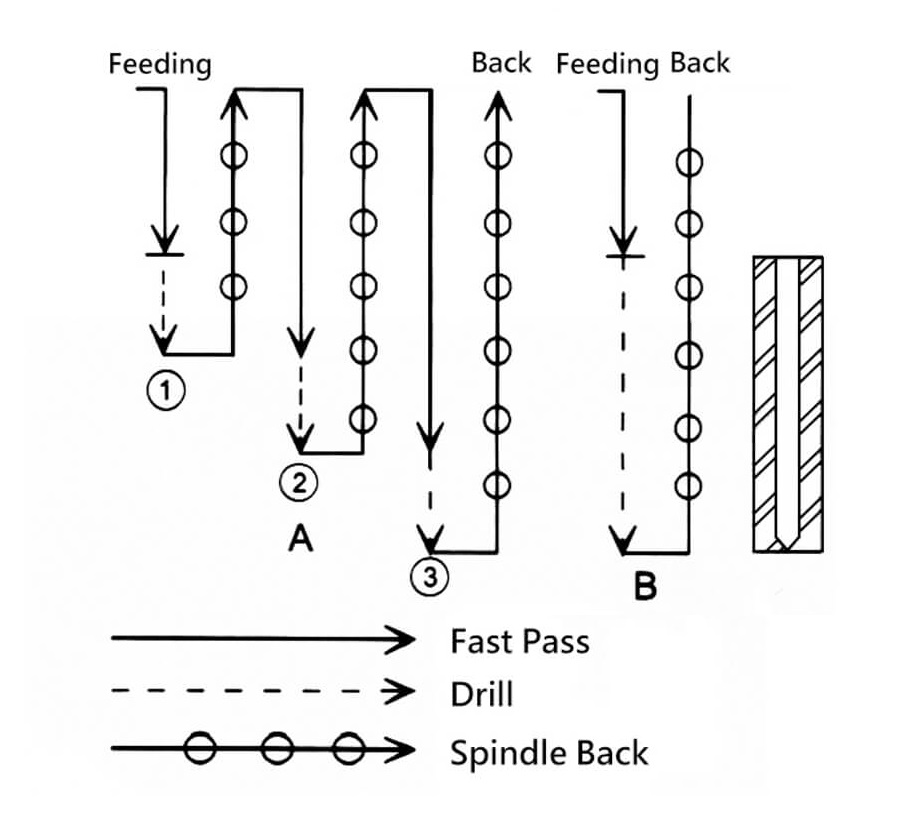

- Beecnc produced Horng Dar brand Bench Drilling Press Machine (Hydraulic Stroke) has 2 sub-types:

(1) Type A : with chip taking out system for deep drilling.

(2) Type B : for normal drilling.

- We have patent rights for this series in both Taiwan and China.

- The pillar drill has an easy adjusting system for stroke speed, making it convenient for operation.

- The tool is stable when used at high feeding speed. It ensures the quality of production.

- Drill bits are we protected in a deep drilling by a chip taking out system.(type A)

- The drill can reposition itself very quick after every chip takings. It saves your time and increases the production volume.

- This series are with a spindle delay timer to set it stop a few seconds in the end of drilling, it keeps the tolerance in depth very well.(0.03mm on spindle with no loading)

- A footswitch is a standard attachment for easier operation.

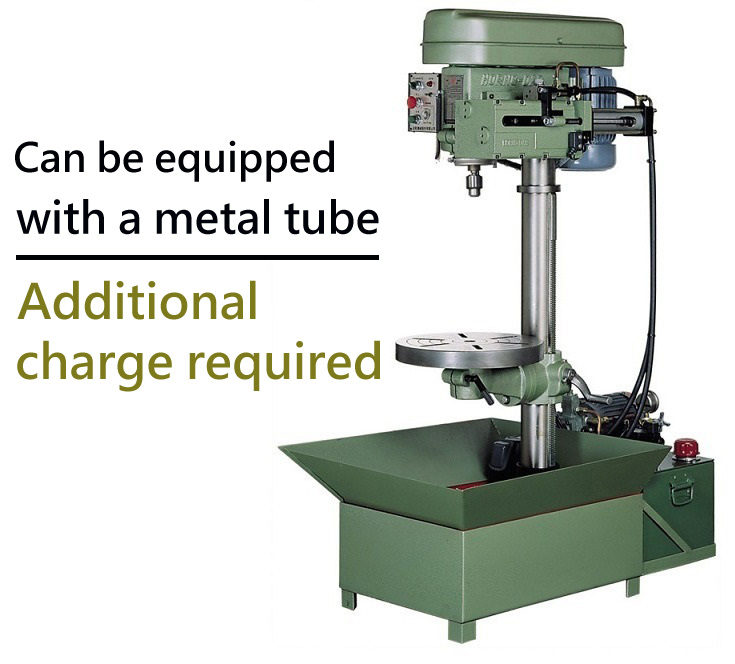

- Drill press machine can be equipped with coolant.

- Our drilling machines are built for durability and superior performance.

- The drilling machine is meticulously crafted with exceptional workmanship and superior precision.

- 100% Made in Taiwan, committed to delivering the best drill press to our customers.

Button Description

Stroke Setting

Cooling system available

6 Key Benefits of Choosing Our Drilling Machine

Best Choice for Drilling Machines

Welcome to visit us

Visit our factory to test Drilling Machine. Schedule your appointment today. Address: 412 No. 115 Kung Yei TIRD, Dali IDN ZONE, Dali District, Taichung City, Taiwan, R.O.C.

6-Months Warranty Assurance

We provide a six-month warranty for all Drilling Machines, ensuring the stability of your machine during initial operations for your peace of mind. Please note that the warranty does not cover belts and bearings, as these items are considered consumables.

Service Techs Support

Our team of factory-trained and certified technicians possesses extensive local manufacturing expertise and is ready to provide you with top-notch Drilling Machine Service. Feel free to contact us at +886-4-24930678 or reach out via Facebook Messenger or WhatsApp.

Guaranteed Spare Parts Availability

Ample Drilling machines spare parts inventory ensures seamless maintenance and replacements.

Customized Services

Need custom drilling machines, drill presses, bench drills, manual and automatic drilling machines, industrial drill presses, pillar drills, fixtures, or jigs?Our team delivers tailored solutions to boost efficiency.

Exceptional

Cost-Performance Ratio

Top-quality Drilling machines at unbeatable prices for the best Cost-Performance ROI.

SHANG ZUAN CO., LTD.

SHANG ZUAN CO., LTD.